ChatGPT:

Reinventing Concrete, the Ancient Roman Way

This article explores how modern researchers are studying the composition of Roman concrete, known for its durability and resilience over millennia, to create more sustainable and long-lasting concrete. By examining the unique chemistry and manufacturing processes Romans used, scientists like MIT chemist Admir Masic and University of Utah geologist Marie Jackson aim to replicate and improve these techniques, reducing the environmental impact of modern concrete production.

Conclusion

Ancient Roman concrete, used in enduring structures like aqueducts and marine walls, holds clues to greener building solutions. Unlike modern Portland cement, which is prone to cracking and accounts for 8% of global carbon emissions, Roman concrete has self-healing properties largely due to its unique blend of quicklime and volcanic ash. Dr. Masic’s research suggests that the “lime clasts” in Roman concrete enabled it to repair itself, while Dr. Jackson’s work highlights the role of volcanic ash, which generated rare minerals that prevented cracks from spreading. Researchers are now experimenting with Roman-inspired additives and alternative materials, like clay-based mixtures, to create concrete that requires less energy to produce and performs better in harsh conditions. If successful, these advancements could reduce the carbon footprint of modern concrete and extend the lifespan of concrete structures.

Key Points

🧱 Ancient Innovation: Roman concrete used unique materials, creating long-lasting and resilient structures still standing today.

🌱 Environmental Impact: Modern concrete production emits 8% of global CO₂, making sustainable alternatives crucial.

🧪 Quicklime for Self-Healing: Dr. Masic’s research found that “lime clasts” in Roman concrete may have allowed self-healing by filling in cracks over time.

🔥 Hot Mixing Process: Roman concrete may have included “hot mixing,” adding quicklime directly with volcanic ash to accelerate hardening.

🔬 Volcanic Ash Properties: Volcanic ash, or pozzolana, helped create strong chemical bonds in Roman concrete, giving it durability.

🧱 Rare Minerals Formation: Over time, volcanic ash-based compounds continued forming rare minerals that prevented crack propagation.

🌊 Marine Testing: Researchers testing Roman-inspired concrete in seawater have seen improved durability and strength over time.

🌍 Low Carbon Footprint: Using clay and heating at lower temperatures than Portland cement can cut concrete’s carbon emissions by 70%.

🏗️ Modern Applications: Civil engineers are exploring Roman-inspired concrete for underwater structures like bridges and reefs.

🍽️ Celebratory Experiment: After a year of testing their concrete in the Gulf of Mexico, researchers saw increased strength and celebrated their success.

Summary

1. Roman Concrete Legacy: The article highlights how Roman concrete structures, many still standing after two millennia, inspire modern scientists to develop sustainable building materials by understanding Roman concrete’s resilience.

2. Environmental Challenge of Modern Concrete: Unlike Roman concrete, modern concrete (Portland cement-based) is prone to cracking and produces 8% of the world’s CO₂ emissions, pushing researchers to find a sustainable solution.

3. Dr. Masic’s Self-Healing Theory: Admir Masic proposes that white “lime clasts” found in Roman concrete are not accidents but intentional elements that enable self-healing by releasing calcium to fill cracks.

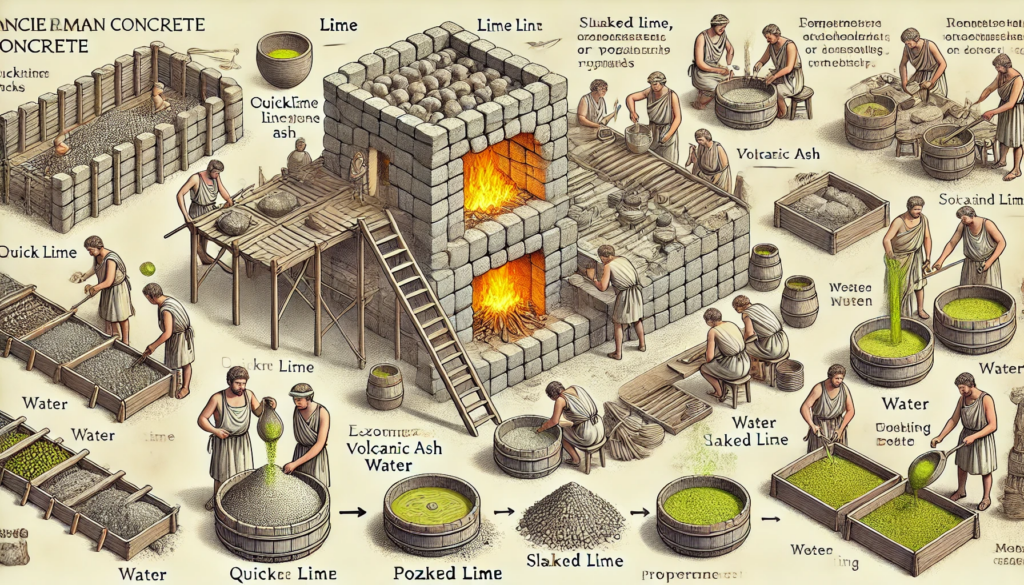

4. Quicklime and Hot Mixing: According to Dr. Masic, Romans used “hot mixing” — adding quicklime directly to volcanic ash, generating high temperatures that made the concrete harden faster and enabled self-repair over time.

5. Pozzolana’s Role in Durability: Geologist Marie Jackson contends that volcanic ash, particularly pozzolana, contributed essential minerals to Roman concrete, strengthening it and preventing cracks.

6. Long-Term Strengthening: Jackson’s studies suggest that Roman concrete continued to gain strength over years as volcanic ash and lime formed rare minerals, contributing to its resilience.

7. Testing in Harsh Conditions: Researchers have replicated Roman-inspired concrete and tested it in seawater, finding it develops more strength over time, similar to ancient Roman marine structures.

8. Reduced Carbon Concrete Innovations: Dr. Ashraf’s team has developed a clay-based concrete that requires lower temperatures than Portland cement, reducing emissions by 70%.

9. Real-World Experiments: Civil engineers like Dr. Ashraf are using Roman-inspired techniques to create concrete for underwater structures in the Gulf of Mexico, where it has shown improved durability.

10. Future Implications: By adopting these ancient techniques and materials, scientists aim to produce eco-friendly, self-healing concrete that can extend infrastructure longevity and reduce carbon emissions significantly.

FAQs

Q: What makes Roman concrete different from modern concrete?

A: Roman concrete, unlike modern Portland cement, has unique self-healing properties due to its use of volcanic ash and quicklime. This combination creates a resilient structure that can repair cracks over time, making it more durable in harsh environments.

Q: Why is modern concrete harmful to the environment?

A: Modern concrete production, mainly through Portland cement, emits around 8% of global CO₂ emissions due to the energy-intensive process required to produce it. Reducing these emissions by adopting alternative methods or additives is a major goal for sustainable construction.

Q: How does Roman concrete “self-heal”?

A: Roman concrete contains small lime clasts that can dissolve and fill cracks when exposed to water. This self-healing feature helps prevent structural damage, as the dissolved lime creates calcium carbonate to reinforce the material.

Q: What role does volcanic ash play in Roman concrete?

A: Volcanic ash, or pozzolana, interacts with lime to form a special binding material that strengthens the concrete. This reaction continues over time, creating rare minerals that enhance durability and reduce crack propagation.

Q: How are researchers applying Roman concrete methods to modern materials?

A: Researchers are experimenting with Roman-inspired additives and alternatives to volcanic ash, like kaolinite-rich clay, to produce concrete that requires less energy, has a lower carbon footprint, and retains durability, especially in marine environments.

Q: What is “hot mixing,” and why is it important?

A: “Hot mixing” involves adding quicklime directly to the concrete mixture, creating high temperatures that accelerate hardening. This technique also produces small, reactive lime clasts that aid in self-healing, making the concrete stronger and more durable.

Q: Can Roman-inspired concrete reduce CO₂ emissions?

A: Yes. By using lower-temperature processes and alternative materials like kaolinite clay, Roman-inspired concrete can reduce emissions by up to 70% compared to traditional Portland cement.

Q: Has Roman-inspired concrete been tested in real-world conditions?

A: Yes. Researchers have tested Roman-inspired concrete in seawater, where it demonstrated improved strength over time, making it suitable for underwater structures like bridges and reefs.

Q: What are some potential applications of this new concrete?

A: Roman-inspired concrete could be used for durable infrastructure in harsh conditions, such as underwater bridges, marine breakwaters, and artificial reefs, where traditional concrete struggles to withstand long-term exposure.

Q: Who are the key researchers in reviving Roman concrete techniques?

A: Key researchers include Dr. Admir Masic from MIT, who studies self-healing properties in lime clasts, and Dr. Marie Jackson from the University of Utah, who explores the role of volcanic ash in Roman concrete’s durability.

Q: Is Roman-inspired concrete available for commercial use?

A: Some Roman-inspired concrete additives, developed from this research, are now available. Companies like DMAT have created products that aim to improve the durability and crack resistance of modern concrete.

ChatGPT:

Beyond their innovative concrete, the Romans excelled in multiple areas of engineering and design, contributing to their reputation for building enduring structures and infrastructure that remain influential:

1. Mastery of the Arch, Vault, and Dome

• Arches: The Romans perfected the use of the arch, allowing them to construct stronger and larger structures, including aqueducts, bridges, and temples. Arches distribute weight evenly, enabling longer spans and greater height.

• Vaults and Domes: Using the arch as a base, they developed vaults and domes, like the one in the Pantheon, which was the largest dome of its kind for centuries. This approach allowed Romans to create expansive interior spaces without internal support columns.

2. Sophisticated Road Networks

• Romans built over 400,000 kilometers of roads across their empire, using precise engineering techniques. Roads were constructed in layers with materials like gravel, stones, and sand, ensuring durability and all-weather usability. This network enabled efficient military movements, trade, and communication, contributing to the empire’s cohesion.

3. Advanced Water Management Systems

• Aqueducts: The Romans engineered aqueducts to transport fresh water from distant sources into cities, ensuring reliable access to clean water for drinking, bathing, and irrigation. The precise gradients they maintained over long distances are remarkable, allowing gravity to do the work.

• Sewage Systems: Cities like Rome had complex sewer systems, including the Cloaca Maxima, one of the earliest sewage systems in the world. This improved sanitation and public health, helping cities thrive.

4. Efficient Urban Planning

• Roman cities were organized using a grid layout, with a central forum, markets, and public buildings. This logical, structured approach to urban planning made cities efficient, manageable, and equipped to handle large populations. Their planning influenced city layouts even into the modern era.

5. Durable Building Materials and Construction Techniques

• Beyond concrete, the Romans were known for their high-quality brick and stone masonry, carefully fitted to reduce the need for mortar. They used materials suited to local environments, often adding resilience to their structures.

• Modular Building: The Romans often used prefabricated elements, which sped up construction and improved consistency. This system allowed for rapid expansion and consistent quality across the empire.

6. Innovations in Heating and Cooling

• Hypocaust System: Romans developed an early form of central heating, called the hypocaust, which directed hot air under floors and through walls. This system was used in public baths and wealthy homes, a remarkable innovation in climate control for its time.

7. Military Engineering

• Roman engineers were skilled at building fortifications, bridges, and siege works quickly and effectively. They created military roads, camps, and fortresses that were both functional and durable, supporting their army’s mobility and strength.

8. Public Works and Social Infrastructure

• Romans invested heavily in public buildings like baths, amphitheaters, and forums. These structures were designed not only for longevity but also for social cohesion, providing places for citizens to gather, relax, and engage in cultural activities. The enduring Colosseum is a testament to their skill in constructing large-scale public buildings.

These combined engineering practices made the Romans not only builders but visionaries. Their ability to integrate functionality, durability, and aesthetics left a lasting legacy that profoundly shaped subsequent architectural and engineering practices across the globe.

Modular design in Roman engineering, though not called that at the time, was a concept that involved creating standardized components or “modules” that could be used interchangeably across different projects. This approach allowed the Romans to efficiently construct buildings, roads, aqueducts, and even military fortifications. Here’s a closer look at the details of modular design and how the Romans applied it in various structures:

1. Standardized Building Components

• Romans created standardized materials, like bricks and tiles, that could be manufactured in uniform sizes and shapes. This was particularly evident in Roman bricks, which were often rectangular and of consistent dimensions.

• Standardized building components enabled easier transport and quicker assembly on-site, especially in distant parts of the Roman Empire. These components could be mass-produced in one location and then transported to construction sites, ensuring that quality and specifications remained consistent.

• Examples include standardized arch blocks, columns, and stone slabs that could be fitted into place without excessive customization, speeding up the construction process.

2. Repeatable Design Patterns

• Romans had specific, repeatable architectural plans for types of buildings such as bathhouses, amphitheaters, basilicas, and military camps. For example, Roman forts were often laid out in a predictable grid pattern with consistent components like walls, gates, and watchtowers, allowing rapid setup in new territories.

• This repeatable design was particularly useful for military engineering. Temporary forts, camps, and other structures were quickly erected using modular units that followed a set design. This flexibility and speed were essential for maintaining control and logistics across vast distances.

3. Interchangeable Parts in Aqueducts and Roads

• Aqueducts, with their repetitive arches and standardized channel widths, used modular elements to maintain a consistent flow of water. Arches in aqueducts, for instance, could be built using pre-sized stone blocks and cemented together with Roman concrete, facilitating a quicker assembly.

• Roads were another example. Romans laid roads using layers of stones and gravel arranged in a similar structure across the empire, creating a durable and uniform road network that allowed for easy repair and maintenance. Modular road-building components could be replicated from one location to another.

4. Ease of Maintenance and Repair

• Modular design made it easier to replace damaged or worn-out parts without disrupting the whole structure. In aqueducts or roads, for example, damaged segments could be replaced without needing a complete overhaul. This adaptability was essential in maintaining large infrastructure over the centuries.

• By using modular components, Romans ensured that repairs required fewer materials and less labor, which helped extend the lifespan of their constructions.

5. Efficient Use of Labor and Resources

• Modular design allowed Romans to use semi-skilled labor effectively, as workers could be trained in specific tasks and repeat them consistently. Skilled workers could create the standardized modules off-site, while on-site laborers performed assembly. This system reduced construction times and kept projects on schedule.

• The ability to work with pre-made components also reduced the need for custom fitting and minimized waste, as materials could be used efficiently across different sites.

6. Adaptability to Different Environments

• Modular design enabled Romans to adapt structures to various geographic locations and environmental conditions. For example, bridge piers and arches could be adjusted in height or width based on the terrain while still using standard parts.

• Similarly, military structures could be adapted to fit the defensive needs of each site while retaining a core modular plan, allowing the Romans to build fortresses that were effective in diverse landscapes.

7. Expansion and Replication

• Modular design facilitated the replication of Roman architecture and engineering across their expanding empire. From North Africa to Britain, structures like temples, roads, and aqueducts followed a recognizable Roman style, giving a cohesive identity to the empire’s infrastructure.

• This consistency made it easier for local workers and architects to adopt Roman engineering methods, further spreading Roman architectural principles and enhancing the empire’s unity.

8. Influence on Later Engineering and Architecture

• The Roman approach to modular design influenced later construction techniques, especially in medieval and early modern Europe, where similar standardized components and repeatable patterns were adopted.

• Modular design principles continue to be relevant in modern architecture and construction, where prefabricated parts, modular building units, and repeatable designs offer flexibility, efficiency, and cost-effectiveness.

In summary, the Roman use of modular design was a foundational element in their engineering prowess, allowing for faster construction, easier maintenance, adaptability across diverse environments, and a unified architectural style throughout their vast empire. This approach not only demonstrated Roman ingenuity but also laid groundwork for construction methodologies that endure to this day.